- Tools: radial arm saw, hammer, chisel, sliding square, pencil [sharp], 8m tape, folding rule, sliding F clamp, hand saw

- safety equipment: ear muffs, safety glasses, safety boots

- Hazards: radial arm saw [clean work area / people safe distance / no loose clothing], chisel [keeping it sharp, chiseling away from you, keeping hands behind what you are chiseling]

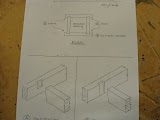

Then some of us went on to do 'Dove tail wall plate joints' [5.5 hours]

First we had to change some of the measurements - 200 to 300 / 47 to 45

Then from the measurements worked out how long each piece of wood was - peice that had A & B joins was 45+90+300+90+45 =570mm / piece B&C was 90+300+90+45=525mm / piece C & D was 90+300+90=480mm / and piece A & D was 45+300+90+45=480mm

cutting the wood to these lengths we then measured out each piece to where each dove tail and sockets are going

Then using a hand saw [where we could] cut out the dove tails and sockets in strips then chiseled them out

using the hand router

using the hand router